Description

Specifications

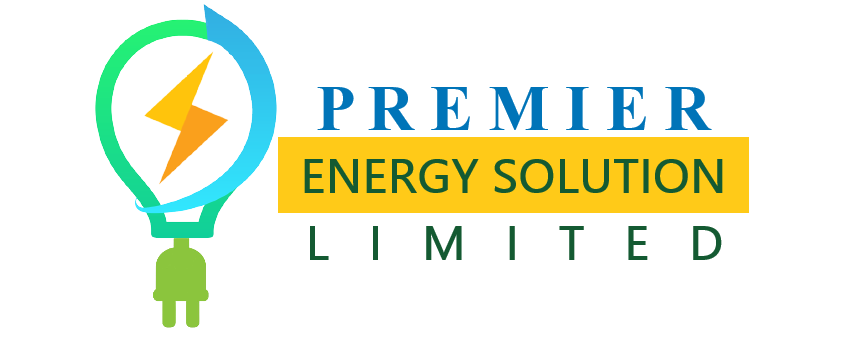

| Type | Chaff Cutter |

|---|---|

| Model | MN9ZPG-0.4T |

| Size | 1300*1150*800mm |

| Blade Quantity | 4 |

| Weight | 85KG |

| Engine | Gasoline Engine |

| Power | 6hp |

| Capacity | 0.4-1.0t/h |

| Application | Farm, Chicken, Duck, Cow, Sheep, Horse, Rabbit etc. |

Description

Features

1 -Steel structure frame, small size, light weight, easy to move.

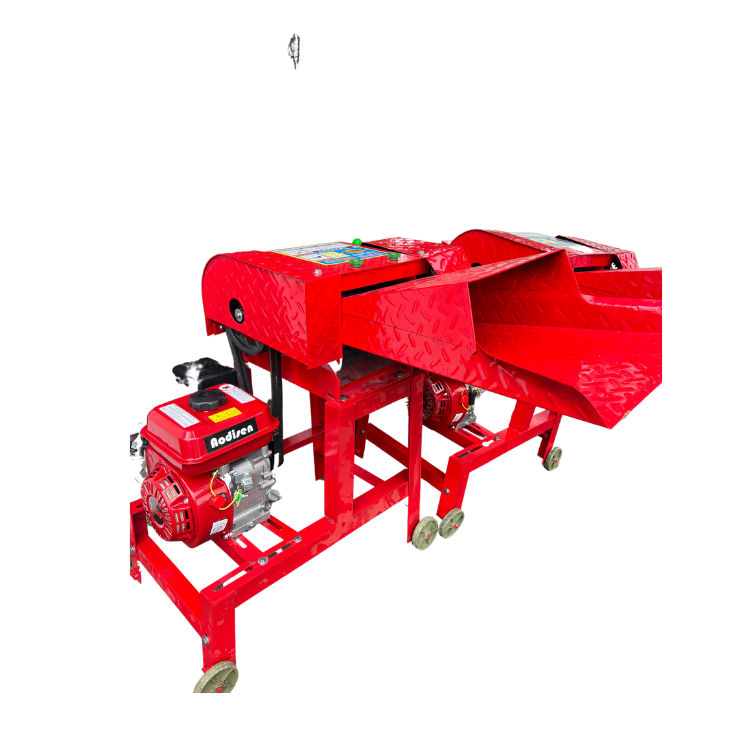

2 -Safety device is designed to prevent knife failure, and the whole machine is safe and reliable.

3 -Advanced feeding mechanism, unique feeding device,smooth feeding, high production efficiency.

4 -The blade is made of high-quality steel, refined by special process, super wear-resistant, high-strength bolt, safe and reliable.

5 -The shell is made of thickened steel plate by continuous welding. The whole machine is shaped with grinding tools. It is beautiful and generous, durable.

Application

It is used for cutting green, dry corn straw, straw, wheat straw and other crop straws and various forages. The processing materials are suitable for raising cattle, sheep, deer, horses, donkeys, etc., and can also be used for bio power generation and papermaking. Ethanol extraction, etc.

Structure and working principle

1 -The machine is composed of upper shell, lower shell, outlet, feed hopper, angle steel frame, hammer piece, cutter, etc.

2 -When crushing, the size of the crushing material is controlled by the size of the mesh, and different mesh can be replaced.

3 -When cutting grass alone, the mesh can be pulled out.

4 -When powder is applied, the special mesh for powder application shall be replaced.

Installation and commissioning

1 -When the machine is working, it should be installed on a flat and solid site.

2 -Install the motor or engine as required.

3 -Before installing the belt, first check whether the rotation direction of index power is consistent with the cutting direction of the hay cutter, and then adjust the installation belt after confirming that there is no error, and make the belt tight properly.

4 -After all parts are adjusted normally and confirmed to be correct, turn on machine supply for test run, and check whether the fastener connections of all parts are loose, and whether there is abnormal sound at all rotating parts.

Prompt

1 -When the machine is working, it should be installed on a flat and solid site.

2 -Install the motor or engine as required.

3 -Before installing the belt, first check whether the rotation direction of index power is consistent with the cutting direction of the hay cutter, and then adjust the installation belt after confirming that there is no error, and make the belt tight properly.

4 -In case of blocking material during operation, it is not allowed to use hand or iron bar to feed it forcibly, and the machine shall be stopped immediately for removal.

5 -When stop working, let the machine idle for two minutes, blow out the dust and weeds in the machine, and then shut down the machine.

Notice

1 -Strictly use the foot wheel of the machine to move in a long distance.

2 -Strictly draw on the surface of the machine to avoid damaging the paint.

3 -Inject proper amount of lubricating oil into each oil filling hole to ensure good lubrication during operation.

4 -Each movable part shall be filled with grease once a day, and the main bearing shall be filled with lithium grease once for 300 hours.

5 -When the blade is blunt, it shall be sharpened in time. When the blade is sharpened, it shall be cooled with water to prevent annealing. When moving the blade, it shall be sharpened at an angle that does not change. When the fixed blade is sharpened, it is not allowed to grind the joint surface of two blades. The weight difference between the symmetrical two moving blades of each machine shall not exceed 50g. The symmetrical two moving blades are not allowed to be used in combination with the old and the new.

6 -When the working angle of the hammer is blunt, the upper cover can be opened, the pin at one end of the pin shaft can be removed, the working angle can be adjusted and installed according to the arrangement diagram of the hammer.

7 -Hammers, pins, blades, can not be self-made to prevent weight loss damage to the whole machine.

8 -In case of abnormal vibration and sound during operation, the machine shall be stopped immediately for inspection. If the bearing is damaged, the bearing of the same type shall be replaced in time.

9 -Check hammers, pin shafts, pins, blades and replace them in time in case of serious wear.

10 -If the machine is not used for a long time, it shall be prevented from being exposed to the sun, and the sundries and water in the machine shall be removed. When the moving knife, fixed knife and paint are grinded off and coated with antirust oil to prevent corrosion. When the machine is used again, the sundries in the machine shall be removed in accordance with the provisions of “installation and commissioning”.

Reviews

There are no reviews yet.